How to reload the linear cutter of the endoscope

What is endoscopic linear cutter reloads

endoscopic linear cutter reloads can be understood as some form of preparation or replacement of the stapler for reuse or new surgical operations. In endoscopic surgery, the stapler may be exhausted due to use. The sutures or other key components inside it need to be replaced in order to perform the next operation, which can be regarded as a "reloading" process.

How to replace the endoscopic linear cutter reloads

To replace the endoscopic linear cutter reloads, the following steps are required

Preparation phase:

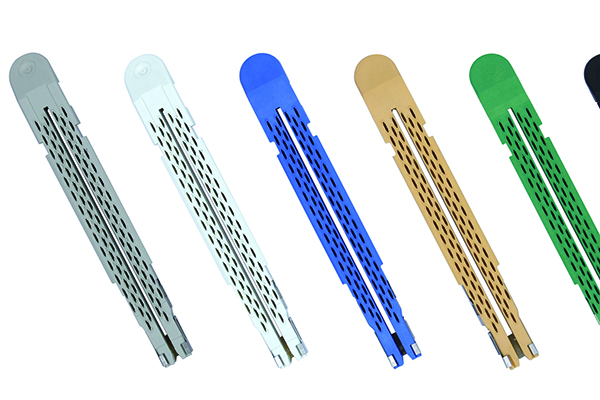

Ensure that the operating environment is clean and sterile, and prepare the required new cutter components (usually including the stapler, base, cutting knife, sleeve and staples, etc.).

Check whether the endoscopic linear cutter and its accessories are intact and have no signs of damage or wear.

Remove the old components:

Gently disassemble the old cutter components according to the specific model of the endoscopic linear cutter and the manufacturer's instructions. This usually involves unlocking or rotating certain parts to release the old components.

Cleaning and inspection:

Before installing the new components, thoroughly clean the relevant parts of the endoscopic linear cutter to ensure that there is no residue or blood to prevent cross infection and ensure safety for the next use

Check whether the jaws and other key components of the endoscope are clean, undamaged, and ready to accept the new components. The cleaning and disinfection process can be regarded as necessary preparation before "reloading" the stapler to ensure that it is in the best condition.

Install new components:

Install the new cutter components onto the endoscopic linear cutter one by one according to the manufacturer's instructions. This usually involves aligning and locking the staple cartridge, base, cutter, etc. into place.

Take care to check that each component is properly installed and that nothing is loose or misaligned. After installing the new components, perform a functional test to ensure that the endoscopic linear cutter is functioning properly. This usually includes checking that the cutting and stapling functions are smooth, that the staples are formed correctly, etc.

Endoscopic linear cutters of different brands and models may have different reloading steps and precautions. Therefore, it is important to follow the detailed instructions provided by the manufacturer. It is very important to maintain aseptic operation throughout the endoscopic linear cutter reloads process, which helps reduce the risk of infection and protect the safety of patients. Due to the differences between different brands and models of endoscopic linear cutters, it is necessary to adjust according to the specific situation. Be sure to disassemble and install after figuring out the matching degree of the equipment.